©NikomMaelao Production / Shutterstock, ©Willmerding

Tyre expert opinion

The damage analysis of (air) tires is a focal point of my work. Through my leading position in the development department of a major tyre manufacturer and more than 30 years as a sworn expert for tyre damage, I have built up a wealth of experience.

Many courts entrust me with the preparation of expert opinions.

I also analyse wheel and chassis damage as a consultant and expert for industrial and private clients.

In the event of disputes between suppliers and vehicle manufacturers, I have also carried out investigations in order to reach an out-of-court agreement on the settlement of damage claims and recalls.

The following is a short overview of the test methods I frequently use.

Visual inspection of the tyre, rim and valve

The first step is the visual inspection of the tyre, rim and valve. In many cases, this already provides an indication of the cause of the damage, which must then be validated by further investigations.

Driving test

Occasionally, driving tests are necessary to determine certain properties. For example, truck tyres were driven under high thermal stress until they burst.

For this purpose, a wheel of a converted vehicle was permanently braked so that high temperatures occurred in the tyre foot. The tire was equipped with several temperature sensors and the process up to the explosion of the tire was measured. In this way, for example, the thermal bead strength could also be determined, which provided important information for operation with high braking power. The wireless data transmission including the sensor technology was developed by us. The reliable fixation of the temperature sensors in the tire was a challenge.

I use the following test tracks for driving tests

- ADAC test area Kempten

- Airport Giengen

- Airport Leipheim

- Porsche Test Site NARDO (Italy)

- Testing station of the Bundeswehr E 41 in Trier

Tyre sections

The cutting of tyres and the creation of a section of tyre is a proven method of assessing the design of a tyre and possible belt edge solutions. For this purpose, the tyre is cut with a saw. The geometric structure of the tyre is thus recognisable and possible solutions between the layers are easily recognisable. By measuring the hardness in the cross-section, it is also possible to draw conclusions about the degree of cross-linking.

X-ray examination

X-ray examination is the best way to detect damage to the steel reinforcement, e.g. in the bead cable or in the tire cord. A remote-controlled handling system in front of an X-ray tube makes it possible to inspect the tire with little effort. In this way, damage to the bead cable, for example, or broken cords can be easily detected.

A scanning electron microscope is available for questions of adhesion to interfaces, material changes and ageing. This allows special questions to be investigated.

Scanning electron microscopy

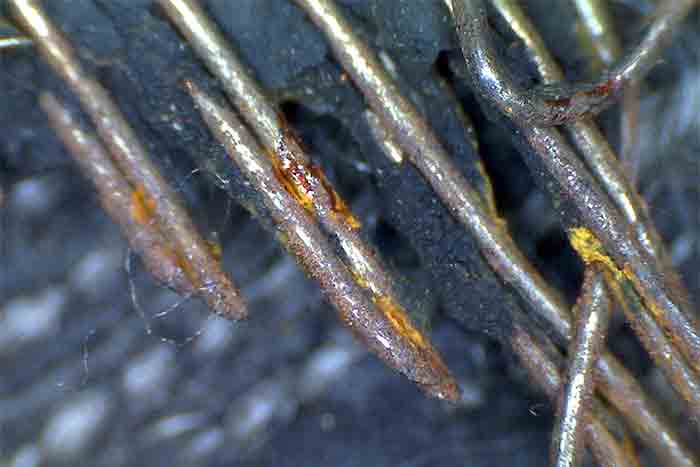

SEM (scanning electron microscopy) can be used to investigate the adhesion of rubber to the surface of steel cord. For this purpose, the parts to be examined must be vaporized with gold. However, the method is very complex and accordingly expensive.

I therefore only use it very rarely.

Light microscopy

Using the light microscope, surfaces and fracture patterns can be analyzed and in many cases fatigue and violent fractures can be distinguished. The microscope can also be used to examine questions of adhesion of rubber and cord relatively easily.

Optical microscopy is relatively simple and inexpensive to apply and is used on almost every tire.

Shearography

In shearography, the tyre is subjected to two pressure conditions with the aid of a vacuum chamber and the inner surface of the tyre is illuminated with laser light. The pressure difference between the two conditions causes the surface to bend (“dent”) as a result of the enclosed air. The optical superposition of the images of both pressure states leads to interference lines at the “dents”, which allow indications of separations between the rubber layers. In this way, separations in the tire structure can be detected at a very early stage.

The prerequisite, however, is that the air inclusion is completely enclosed by material, which is often no longer the case with destroyed tires.

Shearography is used in tire production to evaluate carcasses for retreading. However, I often use this method for damage analysis because it is relatively simple and inexpensive to use.

Laboratory tests

In order to assess objective material characteristics, test specimens can be prepared from the tyre and then the stress-strain characteristics can be determined on tensile testing machines. These tests can also be carried out at elevated temperatures to detect the loss of adhesion.

The ageing of the steel cord rubber adhesion is to be quantified in this way.

Tyre calculation with the finite element method

A calculation of pneumatic tires with the help of the finite element method is possible today and is also carried out by me occasionally in the context of expert opinions. However, the effort is considerable and the correlation to reality has to be proven very carefully.

For development purposes or trend studies, however, the computational analysis of pneumatic tires can be very helpful.